As companies move towards a low-carbon future, the market is increasingly demanding more efficient power semiconductors. The key goal of developing power semiconductor solutions is to minimize the total cost and size of the system while increasing efficiency. As a result, the Intelligent Power Module (IPM) came into being and has become a high-profile solution for the heat pump market. The compact, highly integrated modules with high power density and advanced control and monitoring capabilities are ideal for heat pump applications.

The importance of heat pumps

According to Eurostat, about 50% of all energy consumed in the EU is used for heating and cooling, and more than 70% still comes from fossil fuels (mainly natural gas). In the residential sector, about 80% of final energy consumption is used for indoor and hot water heating.

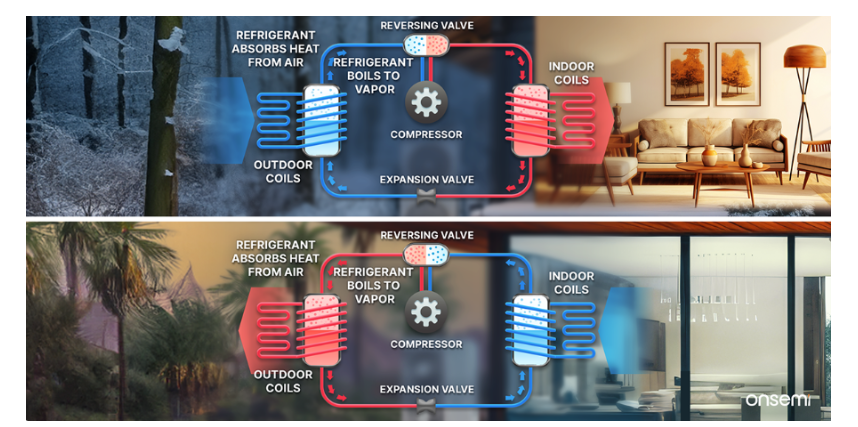

Heat pumps (Figure 1) are powered by electricity and meet heating, cooling and dehumidification needs, making them a proven sustainable heating solution. Heat pumps are an environmentally friendly choice for homes and offices, helping us gradually move away from our dependence on fossil fuels and towards using more renewable energy technologies. With the global focus on energy security and climate commitments, heat pumps are becoming the primary tool for decarbonizing indoor and hot water heating systems.

According to the International Energy Agency (IEA), the number of heat pump installations worldwide is expected to increase from 180 million in 2020 to about 600 million in 2030. Heat pumps are favored because they are at least three times more efficient than traditional fossil-fuel boilers. The number of heat pumps installed in individual buildings is expected to increase from the current 1.5 million units per month to around 5 million units by 2030 (Source: International Energy Agency). In the United States, the Inflation Reduction Act provides tax credits and subsidies for the purchase of heat pumps that cover up to 100% of the cost, depending on the household's eligibility criteria.

Figure 1: How a heat pump works

The role of IPM in improving the efficiency of heat pumps

In a heat pump system, the intelligent power module (IPM) plays a crucial role in controlling the power flow of the inverter compressor and fan. (Figure 2) These modules are responsible for regulating the supply frequency and voltage of the three-phase motor, helping to achieve higher compressor and pump efficiency standards. For example, in refrigeration, a variable frequency system using IPM can reduce energy consumption by 30% compared to a non-variable frequency system.

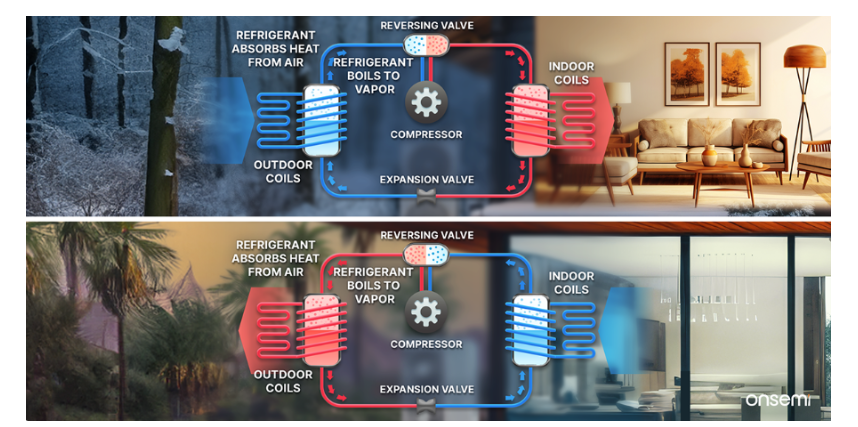

IPM is used in a wide variety of applications and systems. Due to its high level of integration, IPM helps shorten the development cycle, whether in terms of power stages, drivers or protection.

Figure 2: Block diagram of three-phase heat pump

Onsemi recently released its new 1200 V SPM31 IPM family, setting a new standard for three-phase frequency conversion applications. This breakthrough technology not only meets the growing demand for energy savings, but also aims to reduce system costs and improve overall performance. It is foreseeable that the SPM31 IPM with new and improved features will have a profound impact on the heat pump market.

Figure 3:1200 V SPM31 IPM

Higher efficiency and power density

The SPM31 IPM uses the latest 7th generation IGBT Field Cutoff (FS7) technology for high efficiency and robustness. Optimized switching unit design and buffer configuration, as well as narrow electrical parameter distribution, eliminate short-circuit oscillations in single and parallel device operation. In addition, the technology also uses submicron grooved gate cell spacing to increase the channel density and reduce the on-off loss. At the same time, the optimized gate capacitance ensures a smooth switching waveform and low switching losses. The multi-layer FS technology on the emitter side enhances the blocking ability and reduces the drift layer thickness, thus reducing the conduction and switching energy loss. The development of the FS7 IGBT focuses on optimizing Vcesat and Eoff to achieve advanced device performance.

Because the technology significantly reduces electromagnetic interference (EMI), the SPM31 IPM reduces power loss by up to 10 percent, increases power density by up to 9 percent, and reduces IGBT chip size by 20 percent compared to the previous generation. The increased power density helps designers simplify layouts, freeing up valuable space in heat pump systems while improving efficiency. The SPM31 IPM offers A wide range of current rating options ranging from 15 to 35 amps (A).

Figure 4: SPM31 IPM dimensions

Advanced features ensure reliable operation

On's SPM31 IPM is equipped with a range of advanced features to ensure reliable operation. These modules include gate driver ics and various module-level protection features such as:

Undervoltage lock: The SPM31 IPM prevents undervoltage conditions from causing unpredictable operation or damage to the system.

Overcurrent shutdown: This function prevents permanent damage to the system caused by excessive current.

Thermal monitoring: The SPM31 IPM accurately senses temperature to help achieve good thermal management and avoid overheating.

Fault reporting: These modules detect various faults and report them to the system, providing early warning signs of potential problems.

In addition, the SPM31 IPM uses a directly bonded copper substrate (Figure 5) for excellent thermal performance. These features enhance the robustness of the module and make it suitable for various application scenarios. The versatile SPM31 IPM is ideal for a wide range of variable frequency drive applications such as HVAC, heat pumps, variable frequency drives (VFDS), industrial pumps and fans, and servo motors.

Figure 5: Cross-section of the SPM31 IPM

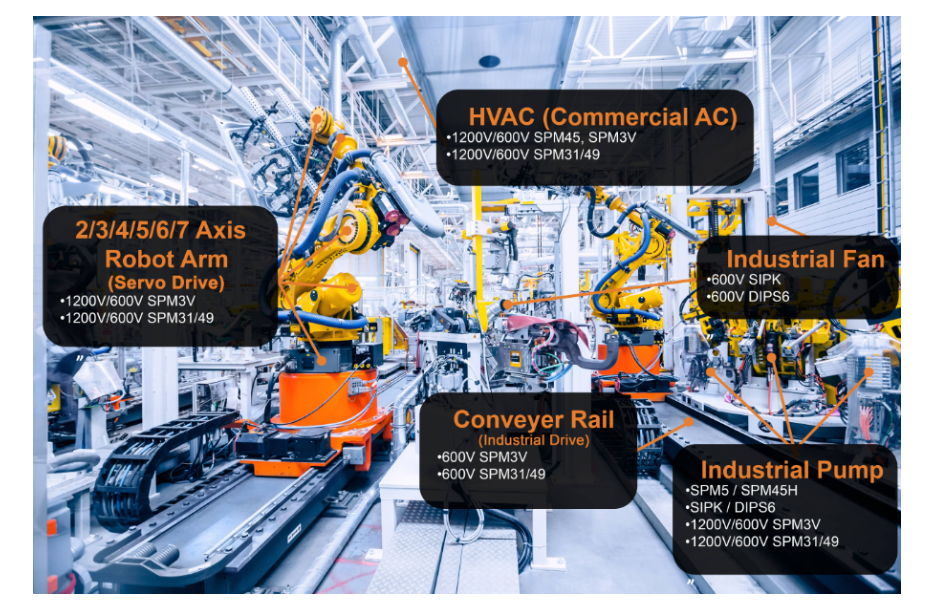

In addition to the SPM31, On also offers several other versatile IPM product lines. (Figure 6)

Figure 6: Application scenario of IPM

These modules are used in a wide range of scenarios, enabling efficient and compact solutions that are expected to revolutionize multiple industries.

A major leap in heat pump applications

The SPM31 IPM brings a major breakthrough for heat pump applications. The IPM is compact and high-performance, enabling engineers to design more efficient, reliable and cost-effective industrial applications.

Learn more about the SPM31 IPM and how these modules are revolutionizing heat pump systems.

Intelligent Power Module (IPM)

High voltage power modules with integrated gate drivers for consumer, industrial and automotive applications. A wide range of three-phase frequency converter modules are available, covering power levels from 50 W to 10 kW. A variety of different topologies are available, including PFC and input bridge rectifier.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.